http//fp.tobyfam.plus.com

Workshop pictures

| Home Page |

| Observatory |

| Astronomy |

| Workshop |

| Gwynedd |

| Holidays |

| Links |

| Work |

| Garden |

| Photography |

| Pinky's Page |

| Emcoturn Log |

| Emcoturn120P

Added this sweet bit of kit, here is a video of it running for the first time under Mach3 control, original steppers and drives video, about 6.5mb some pictures one naked machine, cleaning about 14 years of grease More to follow on the Emcoturn Log page

|

| CNC project-002

X and Y motor mounts are machined, so fitted the X motor after rotating the lead screw (motor now mounted on the left side) Mach settings have improved, I'm now running

at 1050 mm/min. Video early X axis under CNC control 6.5mb Video later run, 350mm/min

|

| CNC project-001

current status: Test motor and drive are hooked up to a

bench supply

|

| Video of X axis under CNC control with temp motor lash-up 8mb |

| Video of X axis jogging with temp motor lash-up 5mb |

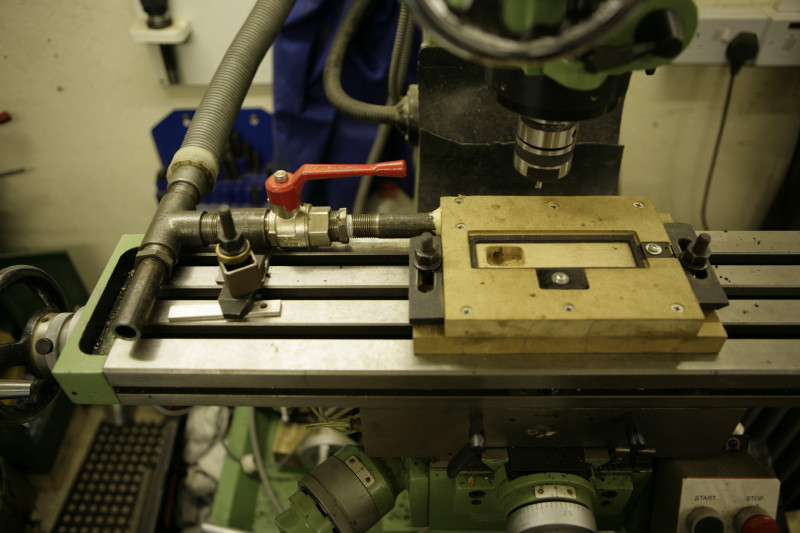

| Vacuum Work holding on the Mill |

The

clamp ready to be used. The

clamp ready to be used.The tube leads to an industrial Vac, which draws trough the restricted T. The valve allows me to turn the vacuum off without having to switch off the Vac. running the Vac dead into the clamp would have overheated the Vac as there would be no air flow over the motor. Next round I'll hope to use a proper Pump, as the Vac means ear-defenders |

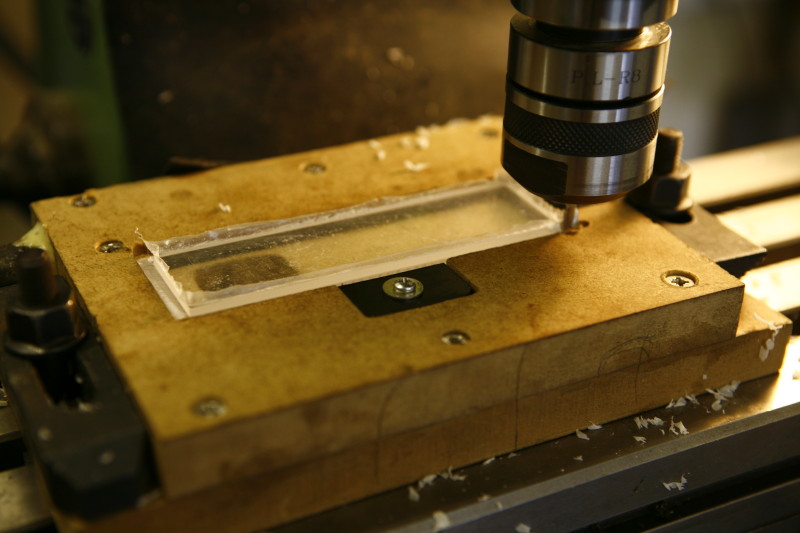

The

clamp in use, this is at the end of the cutting cycle The

clamp in use, this is at the end of the cutting cycle

The rebate is cut in one go |

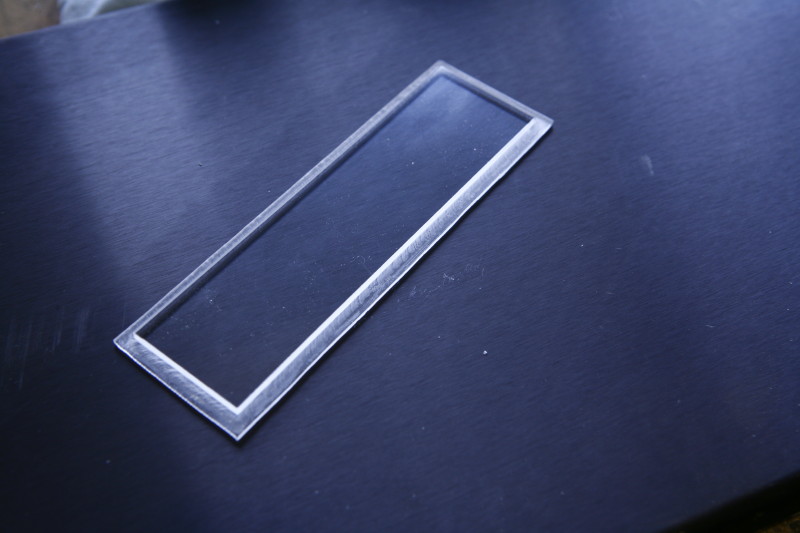

The

end product in the clamp, note the protective film which is left on

at this stage, it simply curls up The

end product in the clamp, note the protective film which is left on

at this stage, it simply curls up |

The

end product ready to go into the console. The

end product ready to go into the console.

a perfect right angle rebate. with razor sharp edges.

|

| CNC control |

Gwyn

in control Gwyn

in control

the PC is running, as is the Inverter, Still need to wire the Interlocks and the Mill.

CNC child splay...... |

left

to his own devices, Gwyn simply picks his bench (special low

version) and puts a bit of wood on it,

so he can stand don it.... left

to his own devices, Gwyn simply picks his bench (special low

version) and puts a bit of wood on it,

so he can stand don it.... |

Stand

made, console partially assembled Stand

made, console partially assembledThe Driver cabinet will be stuck to the MDF board under the console A bit of wiring to be done now :(

|

Console

assembled and filler applied Console

assembled and filler applied |

| New Lathe BH600 from Warco |

The

ramp in the garden The

ramp in the garden |

400Kg

of Lathe 400Kg

of Lathe |

The

legs of the crane where constantly in the way. Here I had to shift

the crate onto a smaller pallet in order to lift the lathe clear of

the crate. First I tried using a ratchet strap, The I simply lifted

the crate with the crane, this dragged it towards the crane and

solved the problem The

legs of the crane where constantly in the way. Here I had to shift

the crate onto a smaller pallet in order to lift the lathe clear of

the crate. First I tried using a ratchet strap, The I simply lifted

the crate with the crane, this dragged it towards the crane and

solved the problem |

|

|

Time

for Earl Grey Time

for Earl Grey |

My

dear wife helped push the monster up the ramp. surprisingly this

worked. My

dear wife helped push the monster up the ramp. surprisingly this

worked.

There was a backup plan using a chain hoist..... |

Possibly

not so clear on the picture, but there was only 40mm play between

the door and the cart. Possibly

not so clear on the picture, but there was only 40mm play between

the door and the cart. |

Lifted

from the cart and repositioned the crane, preparing to lift onto the

stand. Lifted

from the cart and repositioned the crane, preparing to lift onto the

stand.

I then decided to put it on blocks as the lath was not high enough for my liking. |

The

next day, blocks made and fitted. Most bits are back on the machine

( motor, chuck, top-slide and more) The

next day, blocks made and fitted. Most bits are back on the machine

( motor, chuck, top-slide and more)

these where taken off to lighten the machine the whole thing simply roles on 4 bits or round and with a bit of crowbar power it handles quite well

|

In

Place and connected to the inverter. In

Place and connected to the inverter.

|

| Gregoire-Besson disk set project |

David's new "dinky toy"

next to my Landy |

The object of our attention

GB Discordon, where we want to replace the rigid disk sets for cantilever units. |

| As per usual with David jobs,

late nights. This is the mobile Inventor studio

|

| 6 months later and the frenchies have made this from our ideas |

The

cantilever disk sets The

cantilever disk sets |

Custom

made !! Custom

made !! |

The

whole thing The

whole thing |

Changing

the SLA mould pattern for the ART2000s. make a mistake and £800

gone... Changing

the SLA mould pattern for the ART2000s. make a mistake and £800

gone... |

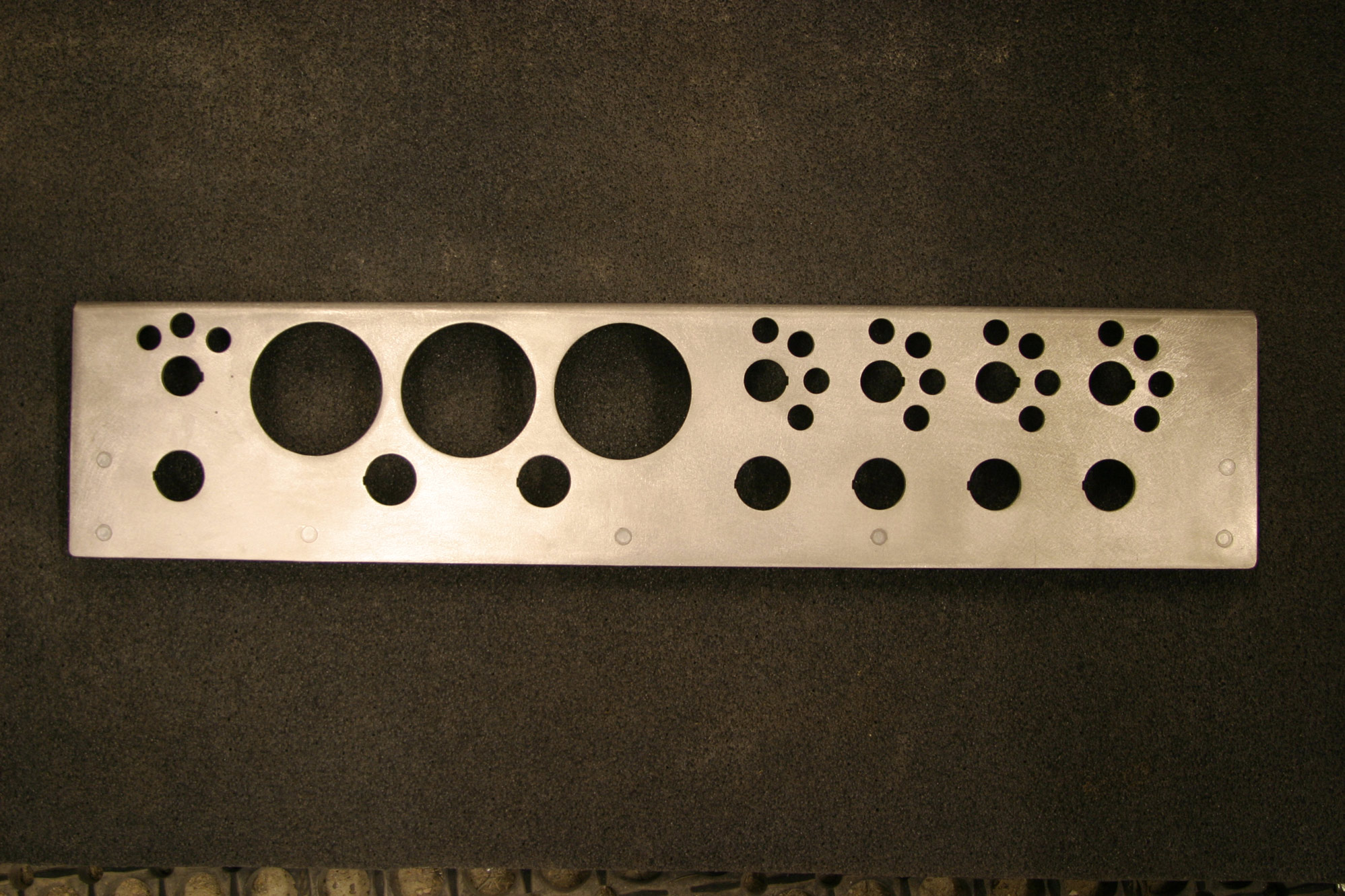

Landy bulkhead pictures |

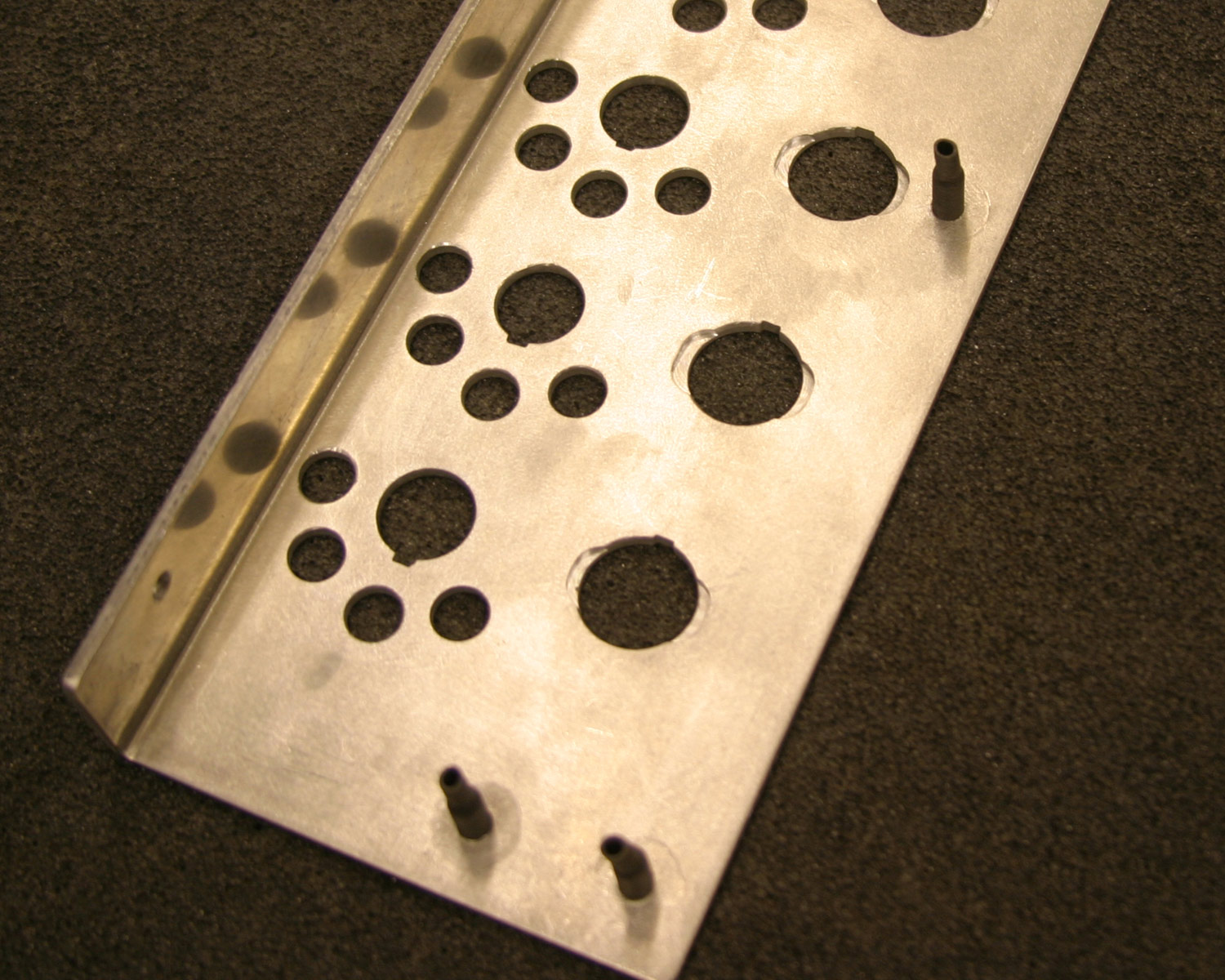

Machined

new front panel for lower parcel shelf in the Landy Machined

new front panel for lower parcel shelf in the Landy |

Machined

new front panel fixings (PEM studs) and relieve machined out for

switches Machined

new front panel fixings (PEM studs) and relieve machined out for

switches

|

trying

out the home made top dash panel trying

out the home made top dash panel |

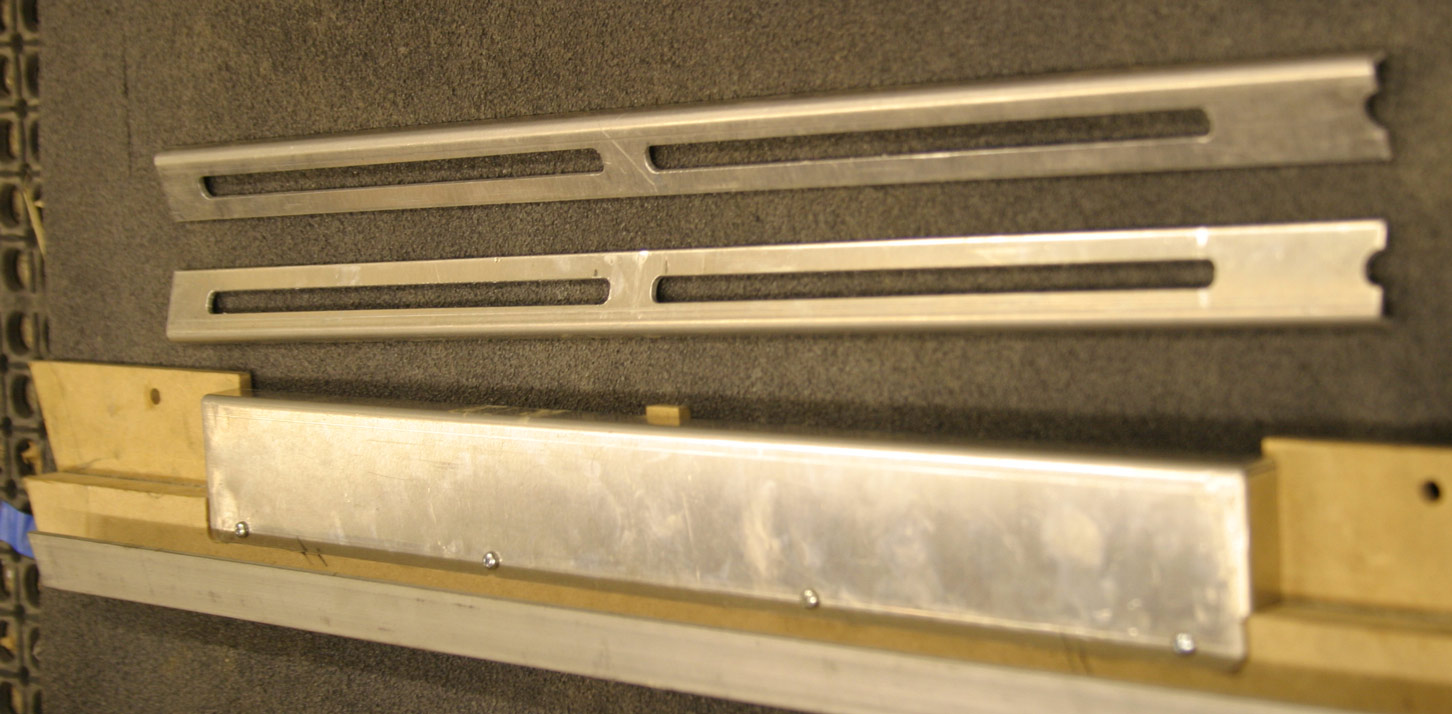

On

top the machines vent flashing, below the underside of the top dash

with the vent plenum chamber On

top the machines vent flashing, below the underside of the top dash

with the vent plenum chamber |

Trying

out the new dash top and the parcel shelf front Trying

out the new dash top and the parcel shelf front |

Workshop pictures |

view

to the entry of the workshop, amongst all the stuff, the band saw

and the home made vertical panel saw view

to the entry of the workshop, amongst all the stuff, the band saw

and the home made vertical panel saw |

View

to the back of the workshop, Myford, Warco mill, and band saw again View

to the back of the workshop, Myford, Warco mill, and band saw again |

Finally

off the crate. Now I can lift it and drive the cart under it to move

the thing

Finally

off the crate. Now I can lift it and drive the cart under it to move

the thing